-

How to Minimize the Cost of Metal Stampings: Expert Insights and Larson Tool & Stamping’s Advantage

Metal stamping is an essential manufacturing process that produces precise, complex parts with high repeatability. From automotive to medical devices and electronics, countless industries rely on stamped components for efficient, high-volume production. However, the cost of producing these stamped parts… Read More >

-

Why Companies Purchase Stamped Parts Overseas, And Benefits Of Manufacturing In The USA

In the global manufacturing landscape, many companies are faced with a critical decision: should they source stamped parts overseas or produce them domestically in the United States? At first glance, offshore sourcing can appear attractive due to perceived cost savings.… Read More >

-

How ISO 9001:2015 Benefits Larson Tool & Stamping’s Customers

In today’s competitive manufacturing industry, quality, efficiency, and reliability are non-negotiable. Larson Tool & Stamping has always been committed to delivering the highest level of quality to its customers and achieving ISO 9001:2015 certification is a testament to that dedication.… Read More >

-

The Larson Tool Advantage: How LEAN and 6S Techniques Benefit Our Customers

At Larson Tool, we take great pride in our commitment to efficiency, quality, and customer satisfaction. Our approach is centered around the principles of LEAN manufacturing and 6S methodology, which drive continuous improvement and operational excellence. These methodologies enable us… Read More >

-

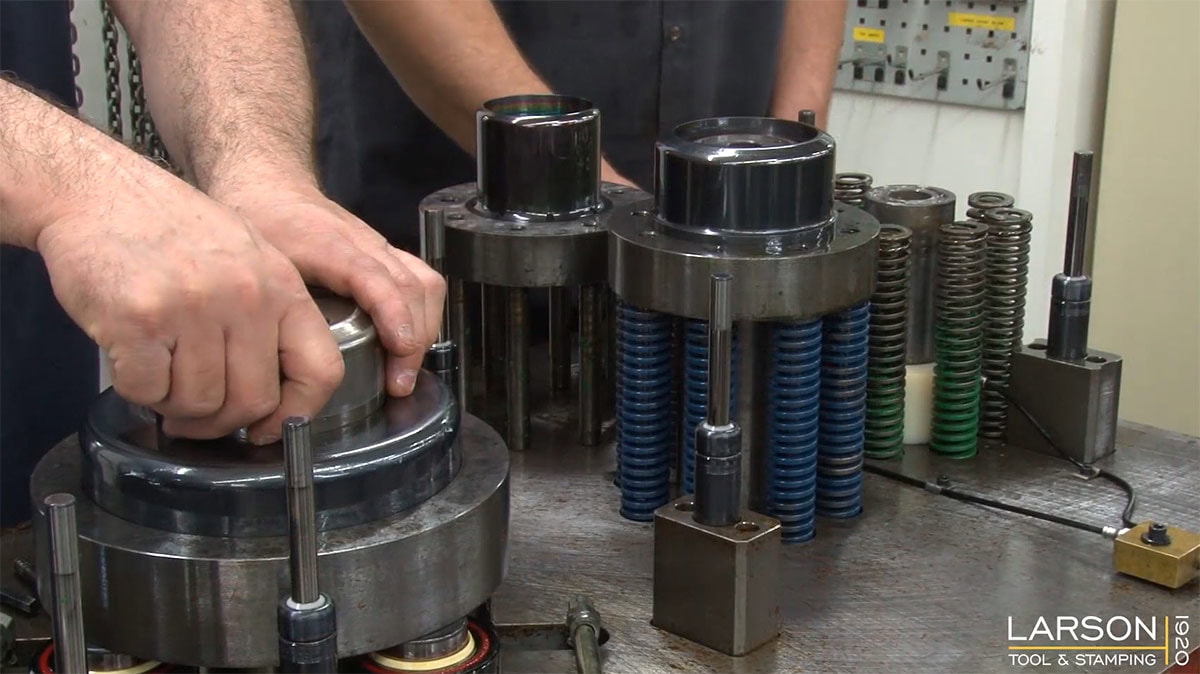

Exploring the Three Types of Stamping Dies: Progressive, Compound, and Transfer

Stamping dies are essential tools in the manufacturing industry, used to shape, cut, and form sheet metal into precise components. Depending on the complexity and requirements of a project, manufacturers typically choose between three main types of stamping dies: progressive,… Read More >

-

Investing in the Future with a Commitment to Apprenticeship and Education

At Larson Tool & Stamping, we understand that the foundation of any successful manufacturing operation lies in the expertise and skill of its workforce. As one of the leading providers of high-precision tooling and stamping solutions, we have built a… Read More >