Learn more about Larson, its impact on the metal stamping industry, and how you can utilize our deep expertise for your next project by downloading these informative resources.

Deep Drawn Stamping Guide

Over the years, we have developed proprietary processes for deep draw stamping and custom precision metal stamping products. As subject-matter experts in the industry, we feel a responsibility to share our expansive knowledge about deep draw stamping—which is why we’ve created this helpful guide on the topic. We’ll walk you through the process, the benefits, the anatomy of deep drawn stamping, and more, to best help you plan your next project or find the right metal stamping partner.

Get the Deep Drawn Stamping Guide

Metal Stamping Design Guide

Metal stamping provides an economical way to produce quantities of parts that possess qualities such as strength, durability, and wear resistance, among others. When designing parts for metal stamping, there are factors that must be assessed: deep draw, material selection, tolerancing, and chemistry. This Metal Stamping Design Guide discusses all of these factors (and more!) and provides some ideas that can help you design a part that optimizes all the features that the metal stamping process offers.

Download the guide and deepen your understanding of metal stamping design.

Get the Metal Stamping Design Guide

Deep Draw Stamping: Metallurgy Case Study

Read about a deep draw stamping project involving a customer that encountered a possible problem after the first production run. There were concerns about the surface roughness of the inner cylinder failing. We were able to find a solution and satisfy the production needs of this customer—and continue to do so by delivering this part to specification—every time. Read the full story in our downloadable case study, “Deep Draw Stamping: Developing Parts for Sustainable Function and Metallurgy Troubleshooting.”

Read the Case Study Now

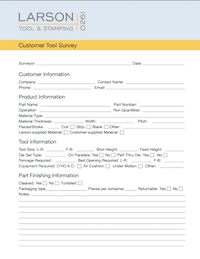

Precision Metal Stamping Tooling Survey

If you’ve decided it might be time to move your tooling, this survey is for you. It will guide you through the information a tooling vendor needs to know to transfer your tooling and transition to a new production agreement seamlessly. Take the survey to properly assess your tooling transfer process.

Take the Survey

Deep Draw Stamping: How a Quality Precision Metal Stamping Supplier Delivers

A Fortune 100 company reached out to Larson Tool & Stamping Company for help in transitioning a product line, which had been handled for years in Europe at multiple vendors, back to the U.S. Due to logistics, language barriers, and crumbling lead times, this Fortune 100 company needed help to complete the project. Larson was asked to manufacture components for a personal protection device. Read the case study to find out how Larson helped this company get through a massive transition, consolidate manufacturing back to the U.S., and meet the needs of their customer base that was growing exponentially.

Download the Case Study

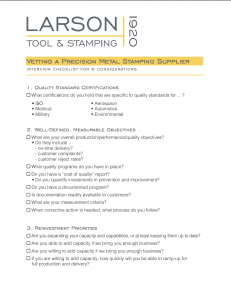

Supplier Interview Checklist Download

Looking for a reliable precision metal stamping supplier? We’ve compiled this interview checklist to guide you through the information-gathering process and help you vet your precision metal stamping suppliers. The clear and structured questions in this checklist will help you have the most productive interview with a prospective metal stamping supplier so you can make the right choice.