Deep Drawing

We have built a reputation in the industry as deep draw experts, creating a proprietary process for deep draw stamping and customized products.

Industry specialists in deep draw, we have massive capacity with our automated assembly to produce deep-drawn shells.

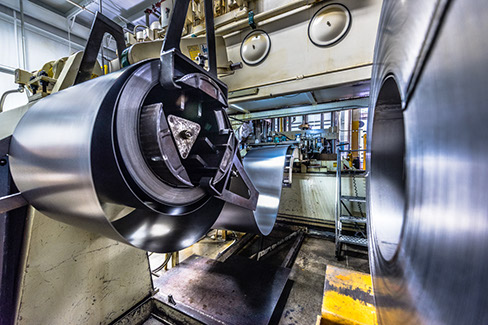

These are 10,000 pound (4.5t or 4,536 kg) coils of draw steel next to a custom-built, hydraulic, fully automated deep draw transfer press line. The range of deep drawn cylinders produced by our deep draw press lines is from 2-1/2″ diameter X 7″ long, to 8″ diameter X 22″ long, with wall thicknesses of .030″ to .090″.

An attentive operator inspects and packs deep-drawn shells from one of our fully automated deep draw transfer press lines.

This 36 inch (91.44 cm) wide coil runs through a zig-zag feed into one of our fully automated deep draw transfer press lines. A zig-zag or staggered feed helps to minimize waste and material savings.

Here a progressive deep draw die, built in-house. It’s in the die splitter, opened up, so it can be washed down and maintained at the wash-down station.