How a Quality Precision Metal Stamping Supplier Delivers

Flexibility. Ingenuity. Process Management. Safety. Quality Assurance. These words should be on the list of what to expect when you trust your metal stamping work to a reputable supplier. Some of these terms offer tangible scenarios processes and procedures in place to ensure quality standards are met and safety measures in place. But what happens and how do you know you can count on your precision metal stamping supplier when the inevitable happens? Forecasts change due to unforeseen circumstances; print tolerances that are unpredictably imprecise; product requirements that dictate changes in materials sourcing. We’ve all been there and know that any number of variables can impact production deadlines.

A quality metal stamping supplier needs to have the flexibility and ingenuity to be able to manage processes old and new on the fly. And do so while maintaining all safety and quality assurance benchmarks. Resiliency, we’ve found, is a hallmark capability that we exemplify at Larson. You won’t see it on our dropdown menu with the likes of Deep Drawn Stamping, Metal Stamping Process, and the others, but it drives all we do. We’d like to tell you about a big project we recently took on. The work with this customer is ongoing, but the ramp up to get it there was pretty remarkable.

Project Details

We provided a massive initiative for a fortune 100 company, which involved transitioning a product line from Europe back to the U.S. Due to logistics, language barriers, and crumbling lead times, this fortune 100 company needed help to complete the project.

In its simplest elements, we were manufacturing components for a personal protection device. The overarching project included:

- Taking existing tools from Europe without full information regarding their wear and tear

- Helping our customer keep inventory costs down by buying their existing raw material

- Transferring a customer-owned production machine to our location

- Meeting a reasonable production schedule

These elements were well within our capabilities. As the project got underway, a number of considerable challenges popped up.

Changing Forecast

This was, by far, the most daunting challenge. The Ebola epidemic coincided with the timeframe within which we received the tools. (Though not meant for protection against Ebola, organizations were ordering the finished device for peripheral protection in affected areas.) We originally had approximately nine months to receive and set up the tools and produce the components. The initial EAU was 30,000 (7,500 per quarter). In the first six months, Larson produced over 45,000 parts with immediate shipment the day they were ready. Necessity dictated that we get up and running within two weeks, which we did.

Print Tolerances

Coming from Europe, and having been handled by multiple vendors, specifications were inconsistent. Tools supplied were unable to hold to the print tolerances provided. The quality requirements of these items changed as we were making parts, requiring Larson to utilize our in-house tool-making abilities and alter or replace tool stations on-the-fly.

Legacy Machine Upkeep

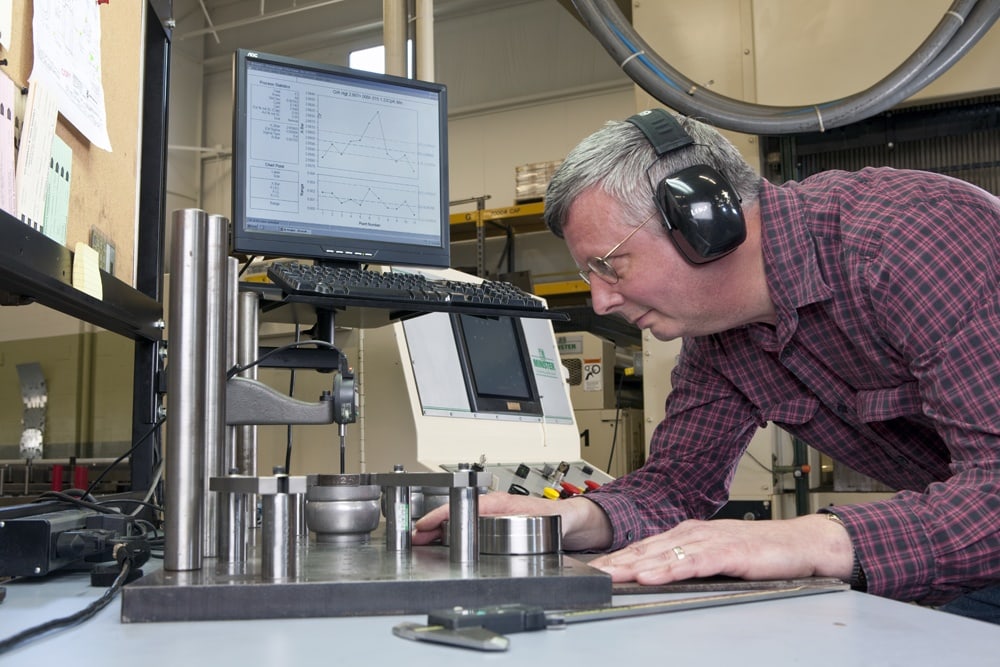

This production machine provided a critical step in making these parts. It was a legacy machine and did not have present-day safety or improvement features. Larson made it safe to run and diagnosed any issues while making parts. We met every quality requirement.

Coordinate Shipments

Due to the volume increase, Larson kept up with and coordinated numerous shipments from a European mill source. This product’s material is obtainable only in Europe, requiring us to air freight and ship via ocean carrier to stay on schedule.

This was a mature product line with a well-established company that did not foresee the inherent transition challenges or forecasting shifts. We were steadfast and agile in our ability to handle multiple contingencies not originally anticipated in the scope of work. We helped them get through a massive transition, consolidate manufacturing back to the U.S., and meet the needs of their customer base that was growing exponentially. We continue to work with them, and they continue to be very satisfied customers.

Larson is uniquely equipped to offer one-stop shopping for precision metal stamping and assemblies. We design, build, test, produce parts, and guarantee our built tools for the life cycle of the product, which means we will service and adapt modifications as needed. Read this case study to see how Larson can help you complete your next project. Download it now.