At Larson Tool & Stamping, we understand that choosing the right material for metal stamping—particularly deep draw stamping—can significantly affect the performance, cost, and quality of the final product. In this blog post, we will explore the pros and cons of various types of steel commonly used in metal stamping: stainless steel (specifically grades 409 and 304), hot-rolled pickled and oiled (HRPO) steel, and cold-rolled steel (CRS). We will delve into their special characteristics, cost differences, and their suitability for different applications.

Understanding Metal Stamping and Deep Draw Stamping

Metal stamping is a manufacturing process that involves shaping metal sheets into desired forms using various techniques, including bending, punching, and deep drawing. Deep draw stamping, in particular, is a method used to create parts with significant depth and complex shapes, such as automotive components, appliances, and various industrial parts.

The choice of steel in this process is crucial, as it impacts the part’s strength, durability, formability, and cost-effectiveness. Below, we’ll examine the characteristics, advantages, and disadvantages of the mentioned steel types.

1. Stainless Steel: Grade 409

Characteristics

Grade 409 stainless steel is a ferritic alloy known for its excellent corrosion resistance, heat resistance, and good weldability. It contains approximately 11% chromium, which provides a certain level of protection against oxidation and rust.

Pros

- Corrosion Resistance: Grade 409 offers better corrosion resistance than many conventional steels, making it suitable for applications exposed to harsh environments, like exhaust systems.

- Heat Resistance: Its ability to withstand high temperatures makes it ideal for automotive applications, where exposure to extreme conditions is common.

- Cost-Effective: Compared to higher-grade stainless steels, grade 409 is relatively affordable, providing a good balance of performance and cost.

Cons

- Limited Formability: While it can be deep drawn, its formability is not as high as other grades of stainless steel, which may lead to challenges in complex shapes.

- Aesthetic Appearance: Grade 409 is less visually appealing than other stainless steels, which might not be suitable for applications where appearance is essential.

2. Stainless Steel: Grade 304

Characteristics

Grade 304 is an austenitic stainless steel known for its excellent corrosion resistance and formability. It contains around 18% chromium and 8% nickel, giving it outstanding mechanical properties.

Pros

- Superior Corrosion Resistance: Grade 304 is highly resistant to a wide range of corrosive environments, making it suitable for food processing and chemical industries.

- Aesthetic Appeal: Grade 304 has a bright, shiny finish that is often desirable in consumer goods and visible components.

Cons

- Higher Cost: The higher alloy content in grade 304 makes it more expensive than grade 409, which can be a significant factor for budget-conscious projects.

- Weldability Issues: While it can be welded, it may require additional care to avoid sensitization, especially in thicker sections.

- Limited Formability: Grade 304 may require additional processes to achieve deep draws, as its strength can make it more challenging to work with in complex shapes

3. Hot-Rolled Pickled and Oiled (HRPO) Steel

Characteristics

HRPO steel is produced by hot rolling a slab of steel and then pickling it to remove scale and oxides. This process results in a smoother surface finish and improved corrosion resistance.

Pros

- Cost-Effective: HRPO steel is often more economical than stainless steels, making it an attractive option for high-volume applications.

- Good Formability: The hot-rolling process enhances formability, making it suitable for deep draw stamping.

- Surface Finish: The pickling process provides a clean surface that can enhance paint adhesion and other coatings.

Cons

- Corrosion Vulnerability: While the pickling process offers some corrosion protection, HRPO steel is still more susceptible to rust than stainless steel, which could limit its applications.

- Mechanical Properties: It may not provide the same level of strength and durability as higher-grade stainless steels, which could be a drawback for certain applications.

4. Cold-Rolled Steel (CRS)

Characteristics

CRS is produced by rolling steel at room temperature, which increases its strength and surface finish. It’s commonly used in applications that require precision and a superior surface quality.

Pros

- High Strength: CRS offers excellent tensile strength and is ideal for parts requiring high durability.

- Excellent Formability: Its excellent ductility allows for complex shapes and deep draw applications, making it a favorite for many manufacturers

- Fine Surface Finish: The cold-rolling process results in a smoother finish, which is advantageous for applications where aesthetics and coatings are important.

- Cost-Effective: Generally, CRS is less expensive than stainless steels while still providing good performance in many applications.

Cons

- Corrosion Resistance: Like HRPO, CRS is not as corrosion resistant as stainless steel, making it less suitable for harsh environments.

Cost Comparisons

When comparing these materials, it’s essential to consider not only the initial costs but also the long-term value. Here’s a general overview of their cost trends:

- Stainless Steel Grade 304: Typically, the most expensive option due to its alloy content and superior properties.

- Stainless Steel Grade 409: More affordable than 304, offering a good balance of cost and performance, especially for less demanding applications.

- HRPO Steel: Generally cost-effective for high-volume applications but can lack the longevity of stainless steel in corrosive environments.

- Cold-Rolled Steel (CRS): Usually less expensive than stainless steel, with a balance of strength and surface quality, but may need protective coatings for corrosion resistance.

Conclusion

The choice of steel for metal stamping, particularly deep draw stamping, depends on various factors, including the intended application, environmental conditions, and budget constraints.

- For applications requiring high corrosion resistance and aesthetic appeal, stainless steel grades 304 and 409 are ideal, with grade 304 being preferable for more demanding environments.

- If cost is a primary concern, HRPO steel offers a good alternative with decent formability and surface quality, while CRS is suitable for high-strength applications where corrosion resistance is less critical.

At Larson Tool & Stamping, we pride ourselves on guiding our clients through the material selection process, ensuring that they make informed decisions that align with their production goals. Understanding the pros and cons of each steel type is vital to optimizing the performance and cost-effectiveness of your stamped parts. By considering the unique characteristics of each option, manufacturers can achieve the best results for their specific needs.

About Larson Tool & Stamping Company

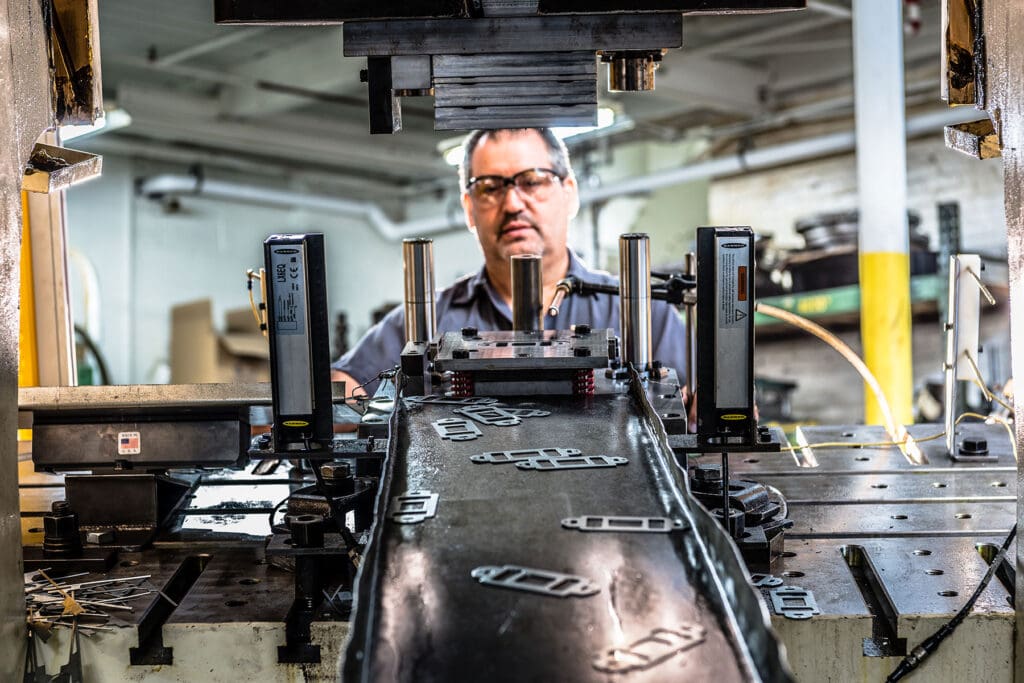

Since its inception in 1920 in Attleboro, MA, Larson Tool & Stamping Company has been making a difference as a valued supplier of precision metal stampings and assemblies to hundreds of companies in the United States. Larson provides high-quality, cost-effective solutions with our wide range of capabilities that include forming, stamping, deep drawing, machining, assembly, brazing, coining, and water-jetting. Through significant investment in leading-edge manufacturing equipment and the loyal support from customers and co-workers, Larson perpetuates the commitment made by our founders to do whatever is necessary to meet and exceed customer expectations.

What all this translates to is that—whether your next project requires progressive die stamping, deep drawing, in-die assembly, precision machining, or value-added operations—Larson is well-equipped to do the job.

Find out first-hand and contact us now to see for yourself: [email protected]