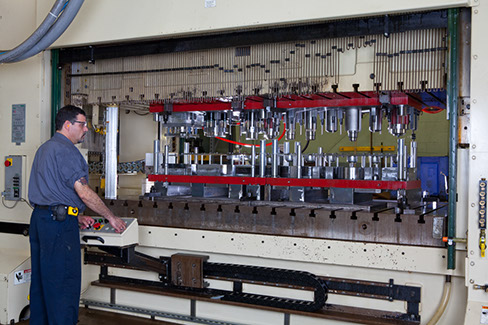

Larson engineers custom solutions using the latest technology and in-house processes—including forming, stamping, proprietary deep drawn stamping, and unique progressive dies.

Precision metal stamping is a process capable of economically producing large quantities of precision parts out of sheet or strip metals at high production rates, usually from dedicated tooling. The precision stamping industry produces components and assemblies that are involved in our everyday lives, from electronics and transportation to more industrial needs.

The essence of the metal stamping process involves driving a flat-faced, sharp-edged tool steel punch through sheet or strip material into a mating die cavity to pierce, trim, and blank the material. This process can be used to yield perforations, trimmed edges, and finished sheet metal parts of all shapes and sizes.

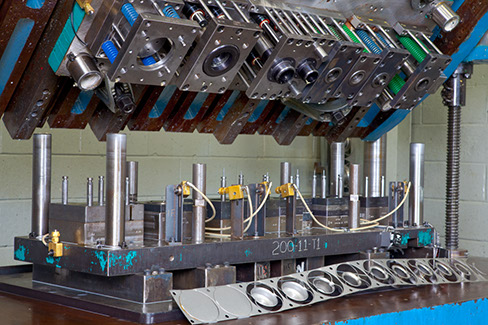

Size, complexity, and volume of production are considered when choosing to use progressive dies in stamping. This complex metal-forming process allows Larson to increase productivity while reducing costs. As the name suggests, progressive die stamping requires stamping at different workstations that perform an individual, progressive iteration of the stamping process until completion. The final part emerges at the end of the operation, and the stock strip is cut away.