Stamping

Larson is a trusted supplier to hundreds of manufacturers and OEMs who rely upon us to consistently deliver precise, high-quality stampings.

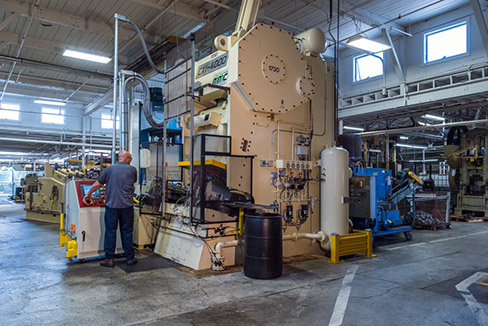

Larson’s modern, coil-fed press room was designed from the ground up, utilizing lean manufacturing principles, and features Minster presses from 180 to 450 tons that can accommodate progressive dies up to 10 feet in length.

Making room for the latest stamping press, Larson literally raised the roof to accommodate this new technology.

Secondary stamping operations help get the job done.

Larson has been building its stamping expertise since 1920, and has the technology to support it.